Dealing with a chainsaw might involve timely replacement of its chain based on its wearing out, usage time, age, and working requirements, but how do select a new replacement chain, and what do the links mean on the chainsaw?

To solve the queries, you first need to know the difference between the 70 vs 72 link chainsaw chain. If you don’t know, rest assured Surferhandy got you covered here!

Each chainsaw chain is built up of multiple parts that sideways work together to make the saw able to cut heavy logs and wood. Each chain has teeth-like outcomings that fit into the chain bar groves ensuring to transfer the of power and cut material swiftly.

But once trying to replace chains, it’s necessary to check how many drive links are required; sometimes users get confused about 70 or 72 links as like many more exist, so for them, we got a differentiation guide to making aware of the facts and terms relevant to the topic. Fond more and get to know more about chainsaw drive links!

70 vs 72 link chainsaw chain- Quick Answer

To select the best drive link chain, whether 70 or 72, consider the pitch, gauge, bar size, and chainsaw equipment model to ensure perfect fitting and efficient working took from the tool.

72 links mean that the chainsaw chain would have 72 drive links empowering the chain to work in great ways compared to 72 representing the chainsaw would have 72 drive links linked together, getting fit to its desired bar size. Both depend on the weight regiment, work, and performance.

So, let’s check out more in-depth!

Link Chainsaw chain and its importance

Replacing your old chain saw would make you confused about what kind of chain to opt for replacement. However, why it’s necessary to have a chain, and what factors determine the selection of a chainsaw chain?

For any chainsaw to operate and cut those heavy woods, it’s the chains that contain drive links, cutters, tie straps, etc., for better transferring of power from the sprocket to the chain, while the tie strip provides the drive link connection with blades for sharp, smooth and butter link cutting.

Those drive links opt on the chain, which covers the chainsaw bar and operates when the engine gets to work.

To select the chainsaw chain, you need to compare the old chainsaw chain specifications, drive ink number, pitch, and gauge to determine what exactly you need. These factors also make differentiation for various chains making each fit for the specific chainsaw.

When I came across a number and alphabets term like 72LGX072G, the chainsaw requires 72 drive links. This 72 only runs for specific bars. Drive links vary; you commonly observe a range from 28-210 per bar size.

If the bar requires 72 drive links and you get 70, it will only sometimes fit that bar. What these drive links are, and how to know which one fits best on what kind of chainsaw bar? Let’s get to the main comparison section. For a glance, check out the table.

Differentiate 70 and 72-link chainsaw chain

| 70 vs 72 link chainsaw chain | |

| 70-link chainsaw chain | 72-link chainsaw chain |

| Drink links | |

| 72LGX072G = 72 Drive Links | 72LGX070G = 70 Drive Link count |

| Pitch | |

| Most common 3/8-Inch | 3/8-Inch, 0.0325 |

| Gauge | |

| 0.050-Inch or 0.325 inch | 0.050-Inch |

| Bar length | |

| Variable based on brand, pitch, and gauge (20-inch bar) | Variable based on brand, pitch, and gauge (18, 20, and 21) |

Drive links

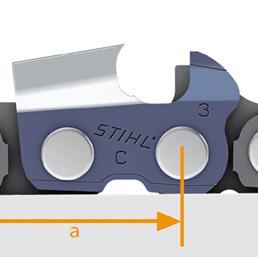

For chainsaws to empower the chains, the drive links provide the medium for transferring. Each chainsaw has its number of drive kinks based on the bar size. Ensure that the drive links must be compatible with the bar length for an easy fit and better working. A chain saw with 72LGX072G requires 23 drive links, while 72LGX070G means the total drive links would be 70. Drive links are the number before the letter ‘G,’ so you can easily identify them.

Pitch

Pitch determines the distance of the drive links. Each saw drive link is placed at a specified distance based on the pitch of the drive socket and the guide bar tip. Various chains have versatile pitches like 0.325″, 0.404″, and 3/8″pitch.

The 72-drive link chainsaw chain mostly uses a 3/8″ chain, the “low profile” or Picco chain. However, for 70-drive links, you might consider 0.325 inches. Besides these, some older chainsaws might go with a 1/2″ pitch chain.

Pitch is important because it determines the overall chain size. After all, the distance between drive links would ultimately be the chain size. What if a bar length of 20 inches requires 72, and you opt for 60? An increased number means more drive links resulting in long lengths unable to fit the desired bar. That’s why to consider pitch for better drive selection and cutting purposes. The wider the distance, the more aggressive the cutting.

Pitch= distance between drive links, rivets divided by 2

Gauge

Drive links might come in various thicknesses, and the term gauge is preferred for measuring. A gauge is a small side outing (tooth-like) from the drive link through which the thickness of the drive link is measured. The thickness or gauge is determined by measuring the drive link portion that easily gets into the guide bar grove.

But why is gauge important? Gauge determines the strength of the chain, but how? Well, it’s a fact that the thicker the gauge, the more powerful the chain, and it works better for professionals and pros.

However, with these, it’s common to have more weight; at that point, you should consider using a weight handled with better width for operational purposes.

For chainsaws, most commonly, gauge sizes vary from .043″ or 1.1mm, 0.050″ or 1.3mm), 0.058″ or 1.5mm, and .063″ or 1.6mm.

A 72-drive link has a 0.050-inch gauge or 1.3mm compared to 70 drive link chain with the same thickness or different based on the product brand and type.

Thickness is independent of the drive links’ number because drive links might be of the same thickness but with numbers as different as 70 and 72 is concerned.

Bar length

While differentiating the 70 vs. 72 drive links bar length can help, it’s obvious that after extensive searching, we find out that despite the different number of drive links, brand versatility does matter, and how is that? Let’s check it out!

Some of the Dayton chainsaw series would require 70 drive links with 3/8″ pitch and 0.050″ for a 20-inch bar and 72 for a 21-inch bar, while for Dolmer, the 72 links with 0.325″ pitch and 0.058″ gauge fit a 20-inch bar based on pitch and gauge. For the Echo series, 72 drivelines with 0.325-inch pitch and 0.050-inch gauge fit an 18-inch bar.

So, do you get it? Each chainsaw would be differential rated for these terms because of requirements variation and the bar fitting specifications. Different bar sizes would fit the same number of drive links because there might be pitch differences or gauges.

Tips

- Always review the manual for drive links requirements, and pitch a gauge.

- Consider bar length with sprockets’ pitch and gauge for a secure and perfect fit.

- Always go with the right size, which can cause an issue with the chainsaw’s working efficiency.

Conclusion

We hope you got the easiest fix for your query with major differentiation and worthy facts to find and select the best chainsaw with either 70 vs 72 link drives. These drive links are usually the teeth-like projection towards the bottom side of the chain securing the chain and based on the bar, so it’s necessary to chocs the right number of drive links.

For more information, consider bar length, gauge, and pitch to get the desired drive link number. For more queries, consult our blog and do share with your friends and family!

Frequently Asked Questions

**What does 70 means on the chainsaw chain?**

Whenever you come across 70 or 70 links meaning the chainsaw bar is stamped with 70 and requires a chain that specifically has 70 drive links to ensure a perfect fit. Drive links vary between chainsaws, and based on working efficiency, pitch requirement, bar size, gauge, and the power capability to deliver to the chain, the drive links number may variate.

**Which chainsaw is best for high or low-drive links?**

The number of drive links is considered per the requirement, but fewer numbers matter when the itch variates. The cutting efficiency leads aggressively if the distance is more between the drive links. It’s the dive link pitch that would ensure cutting efficiency. At the same time, the drive links would empower the cutting.

**Can we go with slightly larger chains?**

No, it’s not of use to go with a loose or larger chain because each bar is designed to accommodate a specific size chain to operate efficiently; else, in-consisting shifting and dropping chains would be the most common problems to encounter. Somehow the same applies to short chains.

A tight chain is even more troublesome and might cause serious damage opts for one. So, opting for the right size, pitch, gauge, and bar size chain is necessary to avoid inconveniences during wood-cutting tasks.