Many consumers are dealing with issues when it comes to Hoscops air stoves. These issues are regarding the technical functioning of the air stove.

Users want the furnace to consume less wood and give high burn time. Once it is implemented in their daily routine, burnout can surely increase.

Most of the time, users might suffer from hopsco air stove problems and issues, not just functional ones but troubleshooting;

it requires better knowledge and technique, so lack of information could cause issues with problem-solving, burner adjustments, and ensuring you set the appliance back to a working state.

To do this, operators must have equipped, trained team of people with knowledge who can deal with the equipment and the process.

It requires critical problem-solving skills and comprehensive procedures. Many issues have arisen that need improvements.

You can follow the below-listed improvements to counter hopsco air stove problems.

Hopsco Air Stove Problems- Quick Answer

- Many customers complain of getting only 6-hour burn time. In this case, you, as a user, must install a damper on the door.

- There are five intake holes near the squirrel box. You need to. The installed damper will regulate the intake of air through the grate.

- The squirrel change is connected to the rheostat switch next to the thermostat with the drawer closed. The button turns off.

- With these improvements installed, the air stove can be increased to give 10 to 12 hours of burn time.

Common Hopsco Air Stove Problems

Following the above steps, users can quickly improve the hopsco air stove problems by adding to the burnout time.

Essential that troubleshooting should be done in an organized and systematic fashion that considers the following basic steps to implement

- Problem Recognition

- Observing problem indicators

- Identifying Problem Solution

- Implementing a corrective plan of action

When a problem is dealt with, evaluating its effect on the process and how a favorable outcome can be produced is necessary. Moreover, at the time, you need to shut off your air stove to troubleshoot or until you resolve the issue.

Once you recognize it, then the answer can be determined. Standard procedures should be followed to return the appliance to a working state and quickly solve the query.

All individuals involved should know the problem and devise a corrective action plan. This plan should address the safety of the procedure.

The expected results should consider solving the problem instead than worsening it.

Flame Impingement issue

Most air stoves and heaters come with a built-in hydrocarbon feed that provides a specific function leading to the air stove working, but once there seems to be a problem with the Flame impingement, it won’t correctly work, leading to issues in the air stove.

Moreover, a high temperature might be a culprit for your infringement to have issues. So, whats next? Inspect or do Visual observation of the burners that cause the flames to get in contact with the tubes.

The operators should troubleshoot or check whether their fired air stoves have infringement issues or to. Try checking the metal temperature to find the cause and then fix it.

Impact on Operations

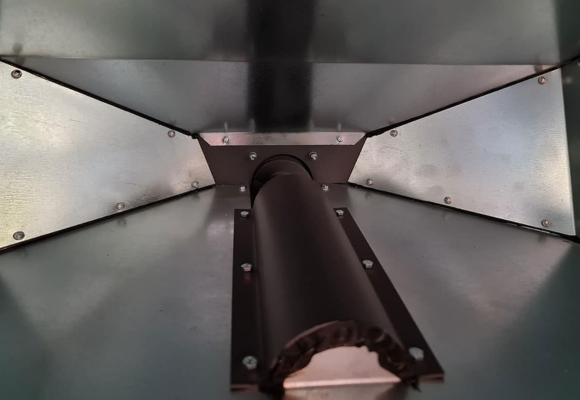

Do you know that The tube inside the air stove furnace is kept safe from overheating because of the coolant inside the tubes? That is why air stoves have carbon steel tubing that remains cool.

Still, at times there are cases where due to extreme heat, the tubing starts to cause carbon buildup that makes an insulating covering on the tubing, so no coolant can cause the tubing to get cool; in that case, there are chances that the tube gets choke with high carbon buildup.

The high carbon flow makes the space less, and after a specific time, it exerts pressure on tubing valves, making it return.

Hot spots are developed in progressive stages. Let’s check out the detailed stages during the process:

- Initially, you would see Dark areas on the side of the tube coating.

- Within the dark areas, various silver or light gray spots are present due to carbon burnt-off.

- The light gray spots become enlarged and begin to cover more area.

- Moreover, some red spots will also appear on the tube’s gray sites. Sometimes, the line will look like almost a chromed piece of pipe.

- At this stage, you can observe that The tube bulging occurs due to high carbon buildup, eventually leading to pinhole leaks.

- Once the limit exceeds, the line ruptures, causing the sit stove to stop operating. Troubleshot the issue by replacing the ruptured and damaged parts.

Warnings on Fan Limit and Damage from Over-Firing or Power Failure

Though many users come across power failure and fan limit issues, in such case scenarios, installing and using furnaces that guarantee safety features and control the fan limit is helpful.

The model of your air stove is a concern with users; it is also helpful for other readers concerned about installing to make use of a wood furnace as an alternative.

Corrective and Prevention Measures to Follow

Amongst the essential things to consider is keeping the flames off the tubes. The first step is that the burner should be adjusted, causing the impingement to get love off the tube.

The registered air confirms that the burner is not open.

Now that you know there seems to be a problem, inspect the gas tips and check for any possible plugging.

In case of plugging exists, that’s causing the flame infringement. Use a gentle brush to clean the site and remove the clogging carefully. Now check the air stove, and it works.

Carefully looking at the burner ensures that the gas tips are appropriately orientated.

If the heater can’t shut off, consider the enlisted four options to troubleshoot the issue.

- Find the block valve and close it. The black valve closure causes less firing rate.

- Remover the burner

- Ensure the firebox remain cool. Get an Increase in the excess air to go with the fix.

- To surpass the overheated pass, imitate the process flow at a high flow

Conclusion

Today in the modern era, users prefer to buy items that will give them high value for the money spent, along with high customer satisfaction.

Many daily casualties must be dealt with technically and tactfully regarding air stoves. Hopsco air stove problems are common and can be frequently fixed if you apply the above-listed improvements listed in the article to your air stove.

It was helpful to make you efficiently deal with the hopsco air stove issues.