The mechanism of the pull cord is simple, and the reason why the pull cord is not engaging the flywheel is because of the stress that comes due to regular use.

If your cord often breaks or ruptures, adjusting it is super easy, i.e., by replacing the cord or handle. However, there might be other issues, including broken or tattered pawls or due damage to the pulley system.

Therefore, to understand why it is damaged and how to cater to it, we need to acknowledge the working mechanism of the lawn mower first.

Learning the lawn mower process helps you know why the pull cord is not engaging the flywheel.

So, to dig deeper into the problem, let’s first learn how the lawn mower works.

Working on the lawn mower:

The lawn mower starts by pulling the cord that ignites the spark. This ignition helps the engine to get started. Once the engine is started, it involves the following parts.

Pulley systems

The pulling cord is twisted around the pulley system, which allows the Rope to pull out before starting the engine.

This pulley system is covered at the top of the mover. And the spring lies at its center. The spring stretches in the pulley system when the Rope is pulled out.

Once the spring returns to its original position, it immediately snaps back the Rope, allowing you to pull the Rope several times instantly.

Flywheel,

The reconciliation of the cord, spring, and Pulley is significant to operate the lawn mower flywheel.

This flywheel is placed below the starter, adjacent to the mover, and Near the crankshaft. Moreover, a magnet lies outside the flywheel, which helps to generate magnetic energy. This energy is sufficient to fire off a High Voltage spark.

Crankshaft

The crankshaft is another component of this machine at the center of the flywheel and turns along with its motion. The crankshaft helps the Piston move up and down, pushing more gas and air into the pulley system.

Besides, if they don’t move faster, your mover will not work appropriately.

Pawls

These are the rotating bars that help to catch ratchet or cog. And when you talk about them as per the mower, they are the plastic Wings attached to the Pulley during the startup process.

When the cord is pulled, the reconciled center starter benefits the flywheel by creating the fastest spinning moment due to the centrifugal force.

They are the most delicate component that causes hindrances in the proper working of the mower. Therefore, if the Pulley or the receiver is damaged, it causes an issue of not letting the code engage with the flywheel.

After glancing over the mechanism, you will quickly understand the problem and the solution to the pull cord not engaging the flywheel.

The Pull cord, not engaging flywheel: common causes.

There are three possible causes of inadequate working of the pull cord.

- Broken Pawls

- Damaged Pulley.

- Rupture reconciled spring

Broken Pawls

The modern Movers’ pawls are made of plastic. However, most of the brands use metal for the production of pawls.

This metal increases the lifespan of the Pawls and also aids in creating tension while spinning out and engaging the flywheel. This part is designed to catch the flywheel, so if it breaks up or gets damaged, it won’t be able to accomplish its function correctly, thus, preventing the engine from turning on.

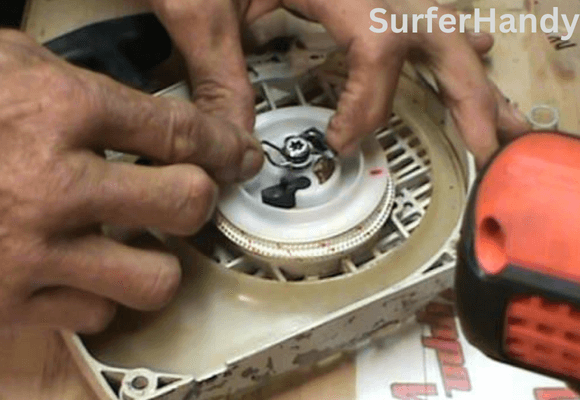

To repair the Broken pawl, follow the steps mentioned below.

Ways to replace the broken pawls

- Before starting, remove the spark plug as it stops the motor from starting.

- Remove the upper or top cover and reveal the pull cord.

- To detach the pawls, remove the center bolt and the cup.

- Examine the pawls to see whether they are damaged or worn out.

- Replace the old pawls with new pawls and then set the removed cup, center bolt, and cover as it is, as they used to be attached before.

Once you are done, pull the cord and investigate whether the mower works. If not, another damaged portion will hinder the working of the pawls.

Deflate pulley system

The Rope that moves the flywheel is covered in a pulley and a reconciling spring. They are made up of plastic and are vulnerable to getting cracked. This broken Pulley created a malfunction in the working of the machine.

So, let’s glance at how to remove the broken Pulley

Technique to remove the fractured Pulley.

- Start by unplugging the spark plug

- Insert the screwdriver to accommodate the spring and Pulley while pulling out the Rope

- Once the Rope is removed, gradually release the screwdriver to create tension in the spring and Pulley.

- To get Pulley free, remove the central bolt and frictional plate

- Now play the new Pulley and rotate it to tighten up the spring

- Pick the screwdriver and insert it in the Pulley to let it in place unless the Rope is re-inserted.

- Remove the screwdriver once the Rope is reconciled, and then reattach the remaining removed part.

Reconciled damaged spring

If the reconciled spring is damaged, it won’t let the cord wrap up in the Pulley when pulled out. Therefore, investing in the complete reconciliation unit is recommended if your spring is broken up.

Whenever you add a new pulley, try to replace the recoil spring because it also helps your mower work effectively. Though it seems expensive, the result is entirely worth it.

Another issue is that it won’t let the Pull cord engage the flywheel.

Apart from these common issues, a few other problems sometimes cause trouble.

The different land mower brands have different manufacturing styles by using components; of plastic or metal. However, Mowers made up of plastic are more vulnerable to damage as they cannot tolerate the stress of consistent use.

Well, the reality is whenever you buy a new mower, you will find several brands that use plastic for the flywheel, which lets them remake the competition regarding the price.

Besides this, most flywheels have a metal Cup to keep them fixed. It is the component where the pawls are attached, so if these cups are worn out, they will create trouble in properly moving the pawls.

As most manufacturers use plastic in their components, it will probably become the most common reason the pull cord does not engage the flywheel.

Last but not least, most lawn mower owners prefer to buy old metal components as they have fewer issues in working and can run consecutively for an hour compared to plastic ones.

Final verdict

In the net shell, if the pull cord is not engaging the flywheel and your lawn seems messy, follow each step mentioned above that helps to make your mover mission accomplice smooth. Lastly, if you replace the whole unit with a plastic one, you might face this problem repeatedly. Therefore you are advised to buy a metal unit that has high durability**.**

Frequently Asked Questions

**What makes the flywheel turn?**

It is a mechanical device that helps to store energy in the form of rotational momentum. This momentum induces torque that makes the flywheel spin.

**What does the flywheel engage?**

The flywheel allows the starter motor to engage due to the gear teeth around its perimeter.

**Can the starter cause damage to the flywheel?**

The loose starter damages the flywheel by knocking off its gear teeth.

**How long do flywheels spin?**

Flywheels spin unless outputs of 100 kW to 2 mW of high power are created in 10 -60 seconds. The output at 125 kW for 16 seconds is quite favorable to execute two mW of energy in approximately one to two seconds.