An essential part of snowblower equipment, the impeller drives snow into the chute and away from the clearing path.

It is in charge of breaking up and removing the snow that the auger pushes ahead and is often situated behind the drill.

An engine or motor usually drives the impeller via belts, pulleys, and wires. The snowblower may not work correctly if the impeller is not rotating, leaving the snow obstructed and the operator unhappy.

Yet, a non-turning snowblower impeller is a typical issue, particularly with older or poorly maintained equipment.

Shear pins, cables, pulleys, bearings, drills, and motor problems are some potential causes of impeller failure.

While some problems can be easily fixed with essential tools and abilities, others require more knowledge and resources.

Identifying the problem’s core cause before making any repairs or replacements is crucial to prevent wasting time, money, and effort.

We’ll look at the causes, signs, and fixes for a snowblower impeller that isn’t rotating in this post, and we’ll also give you some helpful suggestions on how to diagnose and avoid this problem.

You will discover helpful facts and insights that will assist you in maintaining your snowblower and tackling snow removal with ease and confidence, whether you are a rookie or an expert user. So let’s start and discover how to fix a snowblower impeller that won’t turn!

Symptoms of a snowblower impeller not turning

The drill is revolving, but no snow is being discharged via the chute, one of the most evident symptoms of a snowblower impeller not turning. This may lead to uneven or insufficient snow removal, which may be annoying.

When the snow is not correctly driven and builds up in the chute or around the impeller, the snowblower may also clog regularly as another sign.

This can be risky since it can overload or cause the machine to stall. It might also harm the impeller or other components. Unusual sounds or vibrations from the snowblower indicate that the impeller is not rotating.

This might mean that friction or resistance is produced by an impeller stuck, out of alignment, or worn out.

It might also mean that the impeller is being driven irregularly by worn or broken belts, pulleys, or bearings that link it to the engine or motor.

Such noises or vibrations might be concerning and point to a significant problem requiring immediate attention.

In rare circumstances, a non-turning snowblower impeller might lead to an auger malfunction or complete failure.

This might mean that the shear pins connecting the auger to the gearbox or the impeller have failed, allowing the drill to become disconnected from the power source because the auger can abruptly cease operating or separate while in operation, posing a significant safety risk that could result in damage or injury.

Thus, it’s crucial to routinely inspect the auger and the impeller for symptoms of wear, corrosion, or damage and to swap out any necessary shear pins or other parts.

Causes and solutions of a snowblower impeller not turning

There are a variety of causes for a snowblower impeller that is not rotating, from minor problems to serious ones. Among the most frequent causes are:

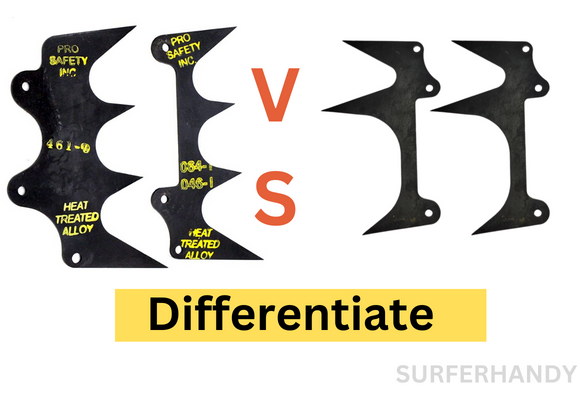

Shearing pins

To protect the impeller and gearbox from harm, shear pins snap when the auger runs into an object like a rock or a stick.

However, if the shear pins are worn out or placed incorrectly, they can break too readily or frequently, which would cause the auger to separate from the impeller and the impeller to cease moving.

To resolve this problem, the shear pins need to be replaced with fresh ones made to your snowblower model’s specifications to resolve this problem. They also need to be correctly positioned and tightened.

Cables and belts

A snowblower impeller not rotating can also be caused by loose, worn, or broken belts and cables that link the impeller to the engine or motor.

The impeller may not get enough power or torque to revolve or rotate unevenly or unpredictably if the belts are sliding or the cables are torn.

You must frequently inspect the belts and cables for indications of wear, tension, or alignment and make adjustments or replacements as necessary to resolve this problem.

Pulleys and bearings:

If the bearings and pulleys that support and direct the impeller shaft are rusty, worn, or broken, this can also result in the impeller of a snowblower not rotating.

The impeller may not revolve smoothly, make odd noises, or vibrate if the bearings are stuck or the pulleys are bent.

To resolve this problem, thoroughly examine the bearings and pulleys and swap out any that exhibit wear or damage using the proper lubricants and equipment.

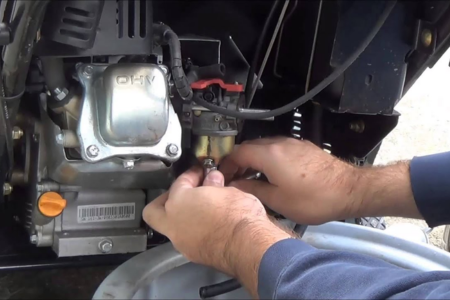

Engine or motor problems:

Lastly, problems with the motor or engine, such as a broken spark plug, a clogged fuel filter, or a carburetor, may also prevent the snowblower impeller from rotating.

The impeller may need more power or fuel to turn or turn too slowly or quickly if the motor or engine is not operating correctly.

Use the manufacturer’s instructions to troubleshoot the motor or engine or hire a trained technician to solve this problem.

Tips to prevent a snowblower impeller not turning:

Use the snowblower sensibly:

Using the snowblower correctly is one of the most crucial aspects of keeping a snowblower impeller from not rotating.

This entails keeping away from rough or icy surfaces that might harm the impeller or the shear pins and from heavy or deep snow that could overload the impeller and stop it from rotating.

Moreover, it entails removing the snow gradually and evenly rather than hurriedly pushing the equipment to its limit.

Carry out routine maintenance:

Regular maintenance of the equipment is another essential element in keeping a snowblower impeller from not rotating.

This includes examining the shear pins, spark plugs, fuel filters, and carburetors for correct operation and cleanliness and checking the belts, cables, bearings, and pulleys for wear, corrosion, or misalignment.

Routine maintenance may guarantee that the snowblower is performing at its optimum and can assist in spotting possible problems before they become more extraordinary.

Maintain appropriate snowblower storage:

A snowblower impeller not rotating may be avoided by storing the snowblower properly.

To prevent corrosion or clogging, the machine must be kept in a dry, spotless, and well-ventilated place, far from any moisture, dust, or debris that could collect.

To avoid fuel deterioration or engine damage, it also entails removing the spark plug and emptying the fuel before putting the machine away for an extended time.

Use high-quality components and accessories.

Last but not least, adopting high-quality components and add-ons can prevent a snowblower impeller from sticking.

This entails utilizing shear pins, belts, cables, bearings, and pulleys constructed of solid and dependable materials developed specifically for the kind of snowblower you are using.

Also, it entails utilizing lubricants or cleaners that are appropriate for the machine and do not lead to buildup or residue, as well as attachments like snow shields or drift cutters that may assist in safeguarding the impeller from harm or obstruction.

By heeding this advice, you can avoid a snowblower impeller from not rotating by keeping your machine well-maintained and ready to handle the next snowstorm.

Conclusion

You may take various measures to identify and resolve a snowblower impeller problem, which can be annoying and dangerous.

You can maintain your snowblower operating smoothly and effectively, even during the harshest winter conditions, by inspecting the shear pins, belts, cables, bearings, and pulleys, doing routine maintenance, and storing it properly.

Frequently Asked Questions

**What stops the snowblower impeller from turning?**

A damaged shear pin, a worn-out or damaged impeller belt, a broken auger or impeller gearbox, or an obstruction in the impeller itself are possible causes of a snowblower impeller not rotating.

**Can I repair a snowblower impeller on my own?**

That depends on what’s causing the issue. If a broken shear pin is a problem, a replacement pin may be installed quickly.

A replacement belt can also be installed if an impeller belt is worn out or otherwise damaged.

But, it could be preferable to look for expert repair services if the problem is more complicated, such as a broken gearbox or an obstruction in the impeller.

**How frequently should I inspect the impeller on my snowblower?**

It’s a good idea to frequently inspect the impeller of your snowblower, especially after each usage or if you detect any performance problems.

Also, routine maintenance inspections, such as checking the belts, cables, and pulleys, can assist in spotting possible problems with the impeller before they worsen.