What if your lawn mower starts well, but after getting warm or doing a couple of yard mowing, it suddenly starts making wired noises and stops?

What next!

Troubleshooting the issue might seem tricky and time-consuming unless you don’t know why this immobility occurs. There might be issues that cause Tuff Torq k46 problems. But which issues any idea?

Don’t panic; we got you covered with the problems, causes, and how to fix the issues related to your Tuff Torq hydraulic transmission K46.

We recommend timely checking the system and maintaining it to avoid the problem. Still, if some persist, our handy, informative guide is a perfect solution to help you troubleshoot and fix it quickly.

Tuff Torq K46 Problems- Quick review!

If your Tuff Torq k46 shows grinding and whining noises while driving it up, shows forward or reverse mode transmission, power loss, worn out seal, default belts, stripped out drive pulley, aged oil, or oil containing metal fillings leading to equipment immobility, the problems lie with your hydraulic transmission system.

All you need is to fix these problems and consider a suitable and compatible choice of fresh oil. After continuous usage, ensure servicing and maintenance to help your equipment last longer without transition issues. Quickly fix the problems to provide tuff top k46 transmission is set back to work.

Tuff Torq K46- Overview!

You might have heard about hydrostatic transmissions in your lawn mower tractors, but what does that mean? How can you troubleshoot problems with the transmission system? Before that, you need to know what Tuff Torq is!

Hydraulic transmissions are manufactured by a global brand Tuff Torq and are one of the most popular hydrostatic transmissions among them; one includes the Tuff Torq K46 hydrostatic transaxle powertrain opted for by most outdoor machinery, including outdoor equipment’s lawn Mowers or tractors to provide stable energy conversion.

The engine’s mechanical energy is converted into working and useful mechanical energy through a hydro hydraulic process by the hydrostatic transmission that empowers the Wheels to be efficiently driven during mower use.

You easily operate the equipment with this transmission with better direction and speed control to get your desired order and speed with the hydraulic flow working.

Tiff Torq transmission has Nifty features, making it highly versatile, efficient, and better for outdoor machinery operation. It lets you decide what control to opt for better efficiency for your working equipment.

Tuff Torq K46 IHT (integrated hydrostatic transaxle) Problems And Causes

Despite the Tuff Torq k46 transmission reliability and high efficiency, sometimes you would get into occasional hiccups with your Tuff Torq transmissions. But why does this transmission occur, and what are the reasons behind them?

To know the reasons, first, check out the transmission-specific problems because sometimes the symptoms may relate to Tuff Torq k46 issues, but that isn’t the case; check these reasons and opt for the desired fix per the required condition.

The common problems within transmission include;

- Worn out seals

- Stripped off drive pulley

- Lubrication issues

- Loss of power

Worn Out Seals

If your Tuff Torq transmission k46 works well, there might be an issue with the seals. The seal is a combined part in the piston pump that holds the piston together, and when the Piston seals are worn out for any reason or wear and tear the seals get worn out leading to poor transmission and less or no conversion to let you drive your lawn mower.

The seal usually gets worn out because of continuous work in harsh overtime conditions or longer distance durations.

The more extreme work, the more chances of the seal wearing out, so if the lawn mower is used continuously during working, its seals might get loose, and after losing it, you might consider it a replacement.

If they do not get timely replaced, the transmission is stopped, and no power is supplied to the Lawnmower; because of this, the tractor will only be able to move up the hill once you replace the seals. The symptoms include slipping and howling noises; high power loss occurs if worn out.

Stripped-Off Drive Pulley

Looking toward the transmission system, you will find a drive pulley on the transmission input shaft. The drive pulley helps in turning the shaft correctly. Nature-wide, the drive pulley is a soft material and is much more prone to wear upon extended use.

So, When The equipment opts continuously without any maintenance, this pulley might get worn out and won’t be able to turn the input shaft correctly. That leads to better transmission in running the equipment. That’s why the lawn mower or equipment would get stopped causing immobility and low performance.

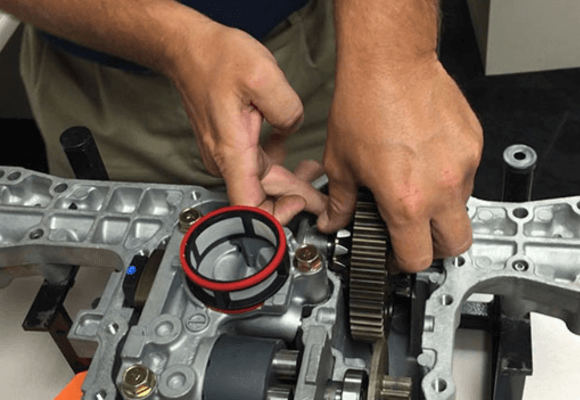

Damaged or worn-out Pistons

Equipment with Pistons or engaging hydraulics required oil to reduce friction and enhance the transmission. Oil reduces overall wear and tear of the entire system, but poor lubrication might lead to issues within the equipment.

What if your lawn mower is suddenly not able to work correctly? There might be a cause for the lubrication. Check out the oil level; if the oil level is less than the desired, you need to refill using a transmission oil to resume the transmission state by letting the mover back to work in no time.

Experts suggest using special transmission oil for your transmission to prevent wearing out; you can also use a gauge to check the oil level transmission. Despite the low-level problem, another issue is bad oil; if added to the engine, the oil causes the drive shaft and input shaft seals to wear out with use or may cause oil leaks within the parts.

The result would be no transmission leading to equipment immobility. The symptoms include complete stiffness, total power loss, and weird whining noises that indicate problems with the lubrication and oil.

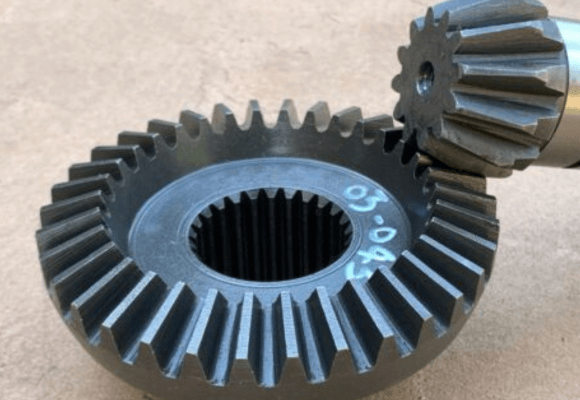

Issue With Gear Set Gears

In the transmission system, you can observe gear set gears with bearings have any transmission. Still, with excessive metal fillings, there is a differential reduction in the gear set gears which causes destruction within the gear parts and leads to no transmission.

But how do metal fillings occur? The metal fillings are again because of aged oil; when oil ages, it loses viscosity and turns to metal fillings that cause transmission issues.

Observe the equipment; if you find its mobility unstable with grinding noises, the problem is with the oil. If you observe any, consider that the oil damaged the gear set because of metal fillings.

Usually, the metal fillings accumulate in oil as a by-product of working transmission. Still, as oil ages, the level gets critical, leading to destruction rather than lubrication.

Poor Maintenance

Your lawn mower integrated hydrostatic transmission might have problems or lead to immobility because of poorly maintained or no service.

Using your equipment continuously without maintenance seems the main problem is poor transmission and equipment storage. The user might miss the lead because their transmissions do not require maintenance or are unserviceable, but that is different.

Opting for your equipment in extreme conditions with no dust prevention and no oil change causes your transmission system to wear out more quickly than those who reasonably maintain it. Maintenance issues would cause any of the parts to get damaged and stop the transmission leading to weird noises initially, and finally, the stoppage of your equipment occurs.

Power Loss

You have clearly understood that in most of the problems, you would observe the loss of power as a symptom which means that there is an issue with the transmission integrated system; to see if the loss of control is related to the transmission, all you need would be to switch off your engine and let the brakes engage after doing that check the transmission deck.

If the Belt is in the right place on the pulley, the problem is with the hydraulic transmission; sometimes, there is dirt and grime accumulation within the Belt that also causes stoppage and will not empower your engine to drive the equipment efficiently and correctly.

Remember that if power is suddenly lost, it doesn’t mean the problem lies with the transmission. If you cold-start the equipment and then, after getting warm, the power is lost means there is an issue within the transmission system.

How To Fix Tuff Torq Problems? Easy Fixes!

After a detailed review of the Tuff Torq problems, it’s pivotal to know each fix to set the transmission back to a working position. Try some of the fixes, but if the problem persists, then consult a suitable expert.

Replace the worn Seals.

Transmission has attached piston pumps with definite seals that wear out over time, leading to failed transmission, so fix the seal by simply replacing them.

Purchase the seal and go for replacement. Check the transmission; if working, you got the problem fixed.

Replace the Drive Pulley

One of the problems is stripped drive pulley; if you observe such, try fixing it by replacing it with replacement parts.

If stripped off, a default pulley won’t reside on the transmission input shaft, so fix it. Usually, it costs less than 45$, so purchase it and replace it with defected one.

Replace or fix the Belt.

If your equipment isn’t working or getting power loss with wired noises, there might be an issue with the Belt.

If the Belt isn’t placed over the pulley, fix it. Before that, clean the Belt and remove dirt or debris. Once done, place the Belt at the exact position on the pulley.

Transmission Oil Replacement

Most of the problems are because of transmission oil; how? You know well in our previous section.

To solve the issue, you only need timely maintenance, using new replacement oil, discarding the old oil, or replacing the oil filter.

But wait! These fixes will only help if you consider high-grade oil. Ensure you purchase the correct recommendable oil for better lubrication and opt for the equipment.

Final Thoughts

What makes your outdoor equipment able to run reliably with better efficiency includes the equipment transmission system, and most commonly, the best one consists of the Tuff Torq k46.

However, due to non-servicing and continuous usage, the Tuff Torq k46 causes problems, so if you face any trouble, shoot it and check out our suggested solution to fix them.

If the transmission still has issues, there might be serious issues other than our enlisted, for which consult a specialized expert to repair your transmission issue. However, mostly our fixes easily handle problems, so you must try them!

Frequently Asked Questions

**What Transmission Oil Does Tuff Torq K46 Transmission Require?**

If you want to keep the tuff Torq k46 transmission in a good state with fine lubrication and better function, try using the Tuff Torq® hydrostatic oil available online and in the aftermarket department. Once you find the oil to be aged, discard the previous one and refuel with the Tuff Torq® hydrostatic oil to ensure better running and working of your lawn mower.

**How Much Does A Transmission Oil Cost?**

For tuff torq, consider transmission oil that costs around 50$, ensuring A high-grade, good quality, and better viscosity. Cheaper options are also available, but they provide a high and compatible grade to let the transmission work freely without equipment immobility or power loss problems or issues.